Influence of curing to physical performance of injection-molded shapes

Process simulation is a widely implemented technology to save time and costs between the first product idea and mass production. A deep understanding of the entire process is key to cost-efficient, high-quality elastomer products. A new measurement method paired with a new material model in SIGMASOFT® now create the option to furtherly increase the precision of mechanical FEAs of the molded shapes.

Aachen, 27.06.2022 – On DKT in Nuremberg (June 27 th-30th, 2022) the software engineer Georg Weinhold will present his abstract on Thursday, June 30th at 12:30 p.m., about a new approach to modeling mechanical properties based on a predecessing simulation of the molding-process with SIGMASOFT®.

Understanding the whole production process is the key to cost-efficient, high-end elastomer products. Nevertheless, production and usage are two separate views of a product. This is represented by two distinct simulation approaches: process simulation and structural analysis. The results of the process simulation are usually not correlated to the mechanical properties and thus information from the injection molding simulation is inaccessible for the structural analysis. This usually results in the assumption of homogenous mechanical parameters for the structural analysis, which is a major simplification.

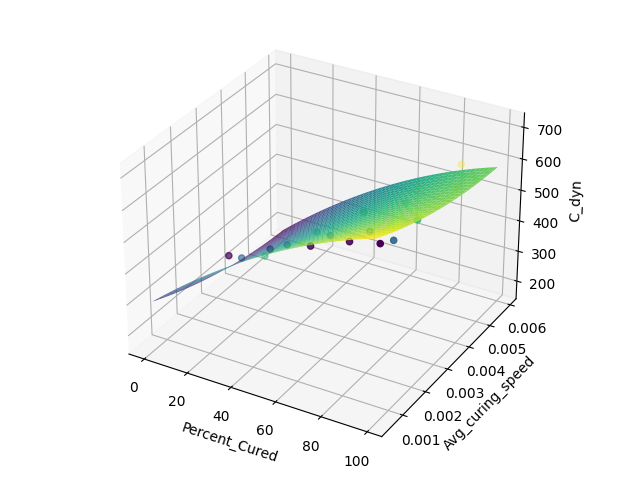

Experiments showed that two process factors dominate the mechanical properties, namely the curing degree and the average curing speed. Hence, locally resolved mechanical properties for high-end structural analysis can only be gained from process simulation. A novel measurement procedure, as well as a new model correlating the process conditions and the mechanical properties of the final part and the required fitting algorithm for the required material parameters, is presented. The calculation of the curing degree, the average curing speed, and desired mechanical parameters for structural analysis are seamlessly integrated into the injection molding simulation software SIGMASOFT®.

The paper „Integrative simulation of mechanical behavior of injection molded parts“ created in partnership with PoIymer Competence Center Leoben, demonstrates the significant impact of the production process on the mechanical performance of the molded part.

In this contribution, it will be shown that the production process is significantly influencing the mechanical properties of the final part. An experimental strategy on how to characterize the connection between the production process and final properties will be shown. Moreover, a novel approach to model the mechanical properties of the final part based on a production process simulation will be presented.