The Best Tool for PIM Simulations

The challenge of reducing the development times of your new parts and reducing iteration loops is omnipresent. SIGMASOFT® MIM/CIM offers the possibility to simulate the powder injection molding processes according to your special needs in the PIM (Powder Injection Molding) industry.

Virtual Molding instead of injection molding simulation: Because feedstocks are not thermoplastics!

We know how important it is to accurately predict thermal phenomena in the mold for PIM applications. In highly temperature-sensitive processing, the mold is crucial for processability, cycle times, and the quality of the green part. With SIGMASOFT® MIM/CIM you can take a look inside your mold even before it is built.

SIGMASOFT® VIRTUAL MOLDING SUPPORTS SOLVING COMPLEX CHALLENGES IN INJECTION MOLDING FROM DESIGN TO PROCESSING.

WHAT YOU CAN EXPECT FROM SIGMASOFT® MIM/CIM:

- Compare different tempering concepts and their influence on the process and part quality

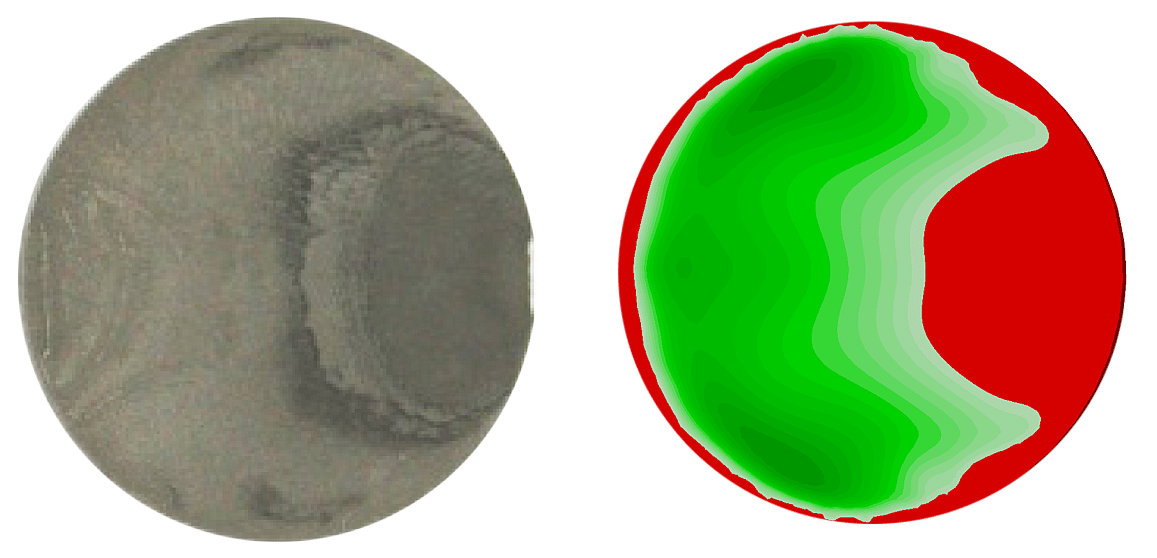

- Predict filling behavior and fluid dynamic phenomena such as free jetting, fountain flow, and plug flow

- Identify shear-induced segregation areas

- Consider disproportionately increased viscosities in the low shear rate range

- Simulate fill-induced deformation of inserts and cores

- Perform clamping force predictions, holding or packing pressure calculations

- Use FEM interfaces

VIRTUAL MOLDING INSTEAD OF JUST SIMULATION:

THE MOLD MAKES THE DIFFERENCE!

With Virtual Molding technology, you create the same process conditions as on your machine and can virtually compare tempering concepts. Intelligent automatic meshing algorithms let you mesh a complete mold in less than five minutes and mesh repairs of any kind are a thing of the past. Take a look inside the mold while it is running.

MAKE SIGMASOFT®

YOUR TOOL AND …

... YOU WILL GET MORE OUT OF YOUR PROJECTS!

OUR IN-HOUSE DEVELOPMENT AND THE TEAM OF EXPERIENCED ENGINEERS IS YOUR SERVICE!

Successful injection molding simulation requires the direct contact between the users and a competent engineering team. Therefore, our solution service, customer support as well as application-oriented software developers work closely together with you for your success!

SIGMASOFT® MIM/CIM

INFORMATION FOR YOU TO DOWNLOAD!

YOUR INSIGHT INTO OUR CASE STUDIES:

Casestudy

Avoidance of surface defects through uniform particle distribution in MIM feedstocks