After production crack formation could be observed on one side of a suspension bushing which caused a malfunction (Fig. 1). The molder reached out to SIGMA to analyze the possible reasons for this failure.

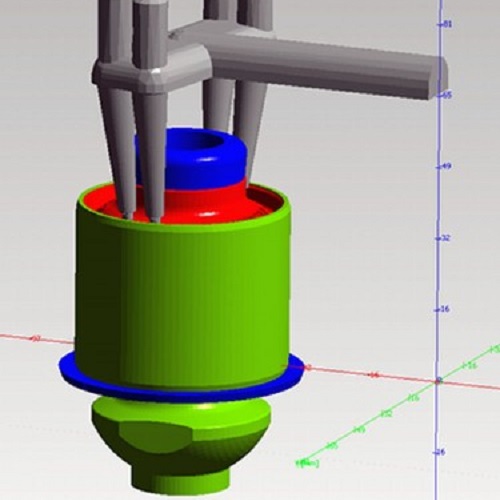

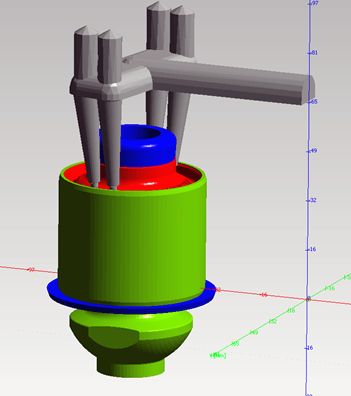

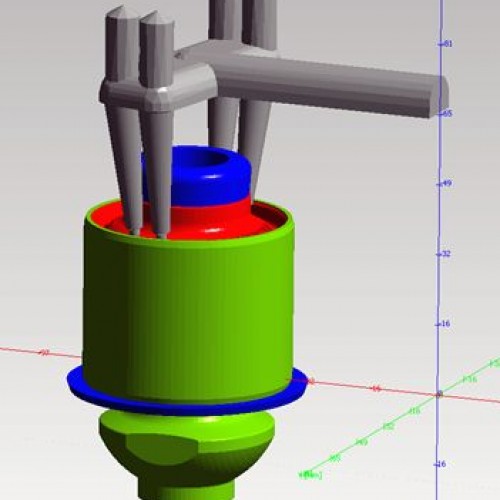

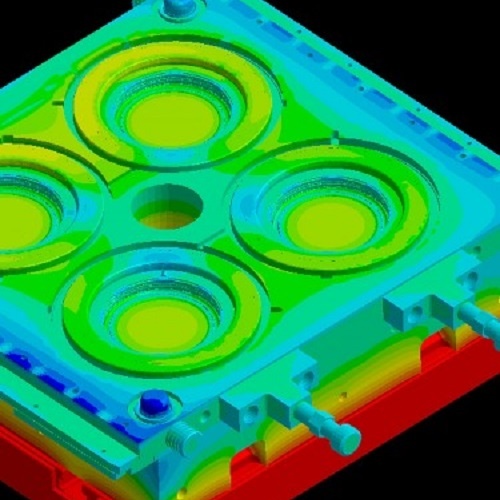

The part was simulated together with the full mold and all process parameters to achieve a realistic representation and to consider all factors influencing the cracking: rubber part, runner system, metallic insert, contour providing plastic inserts. In this way, the real production could exactly be reproduced over several molding cycles (Fig. 2).

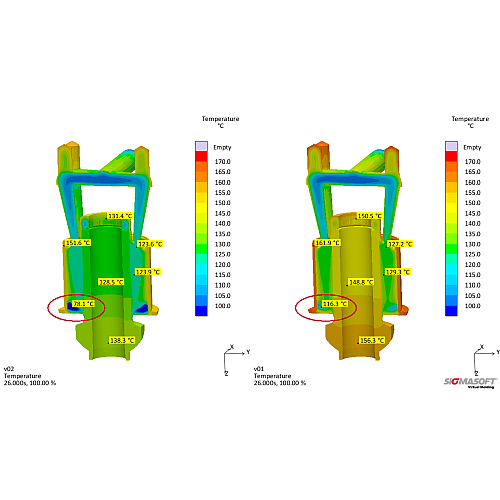

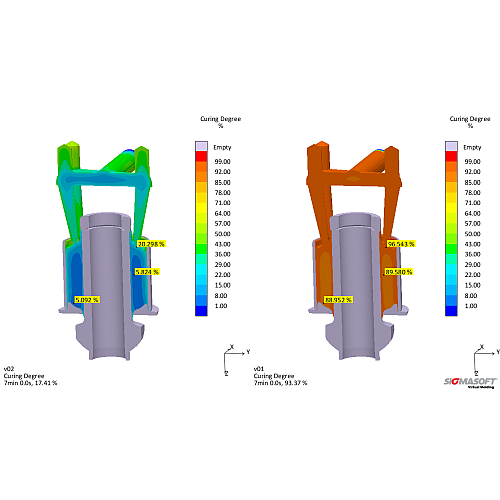

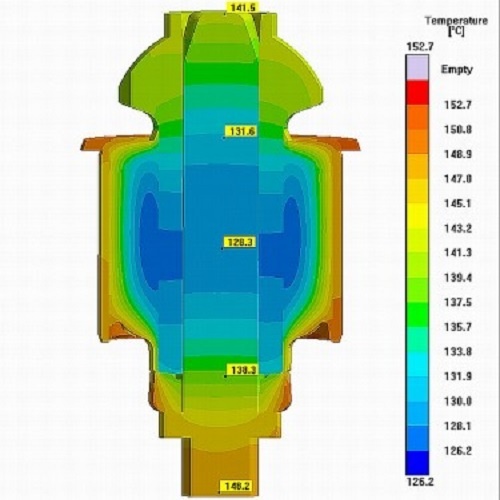

The analysis of the current status showed big differences of the temperatures within the rubber part. The temperatures of the outer regions were much higher compared to the inner regions, due to the thickness of the metal insert. Additionally, it became evident that the plastic insert (PEEK) blocked the heat transfer into the rubber. Thus, it was not possible to reach the necessary curing inside the critical area (circled in Fig. 3, left). Even after a cycle time of 420 s (395 s heating time) there was still significant variation of the curing throughout the part and – even more important – an average curing degree of only 20%, which was distinctly too low (Fig. 4, left).

Possible counter measures include a longer cycle time (resulting in higher production costs) or the optimization of the curing behavior inside the part. It was proposed to preheat the inserts to 100°C. This change was included into the virtual process and a second thermal rheological analysis of the filling, holding and heating phase was performed. The preheated inserts led to a more homogenous temperature distribution inside the part. In the critical area the temperature could be increased by 40°C with this approach (Fig. 3, right). The higher average temperature, the more homogenous temperature distribution and the bigger energy amount available (mostly in the metal inserts) led to a higher curing degree of 93% instead of 20% after a cycle time of 420 s (Fig. 4, right). Thus, the warpage induced by curing was also reduced.

Besides achieving a higher curing degree in the critical area (which improves the local mechanical strength), the local stresses could also be reduced. Both together prevent the cracking of the part. The problem of crack formation in the suspension bushing thus could be avoided by preheating the inserts. A possible additional reduction of the cycle time was not investigated.