Optimization of pressure demand and clamping force in injection molding

A realistic calculation of the clamping force and pressure demand is essential to choose the right size of an injection molding machine and its clamping unit. Due to the realistic reproduction of the process conditions SIGMASOFT® Virtual Molding delivers the necessary information to make the right decision, reducing energy costs and ensuring a smooth production. Two example cases illustrate these benefits.

When designing an injection mold, several requirements are taken into account. Among the considerations are the clamping force and the inlet pressure, which determine how robust the mold is and how large should be the capacity of the injection molding machine. Once the injection unit goes into production, the worst scenario would be to find out the machine or the mold should be more robust.

An injection molding unit that is too small cannot produce the necessary pressure during the filling phase, with the result that the cavity will not be completely filled. Several factors affect the pressure demand in a mold, and if one of these effects is ignored, the pressure calculation may be inaccurate, thus leading to the selection of the wrong machine. While selecting a larger clamping unit is an option to stay “on the safe side”, due to the ever increasing energy costs, it is also unwise. Therefore, the best option left is to look at the big picture, and to evaluate the pressure demand considering all the influential effects and the possible production scenarios.

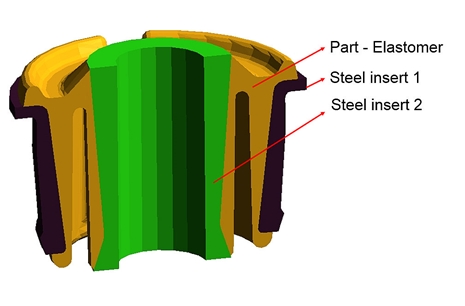

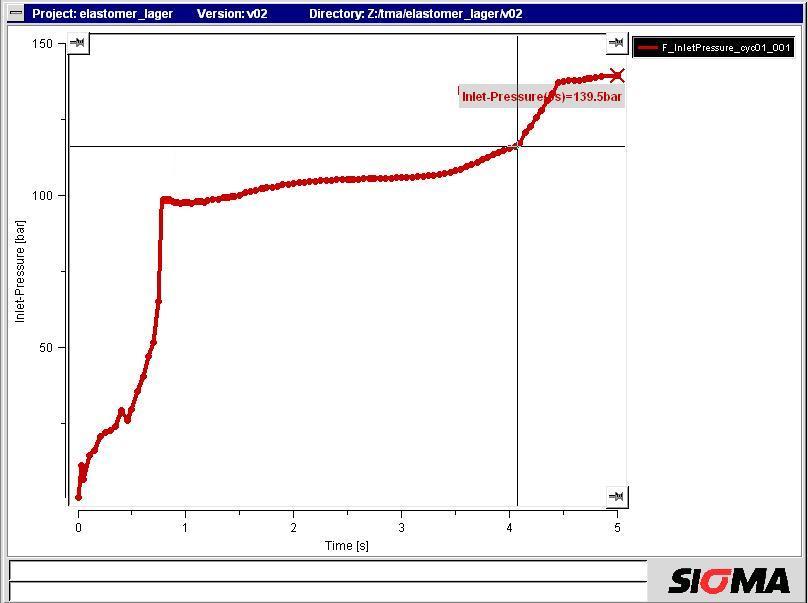

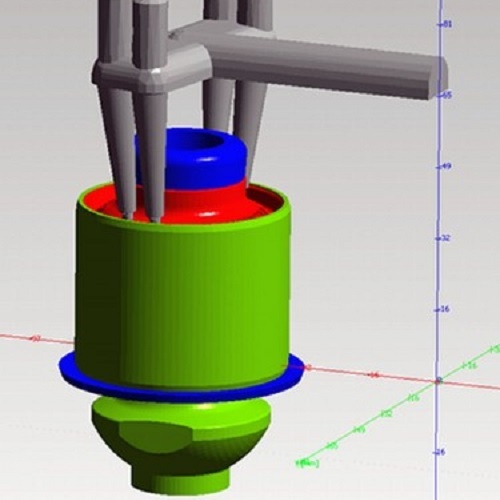

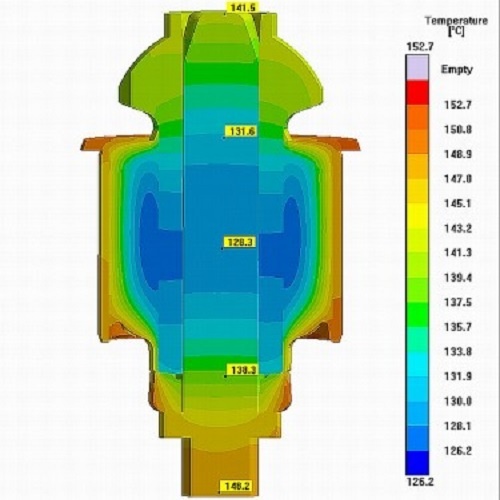

The elastomer part in Figure 1 had to be molded with two steel inserts. In this case, it was necessary to determine whether the machine size readily available was enough to satisfy the pressure demand of the mold. A first scenario was simulated with SIGMASOFT® Virtual Molding. The production conditions were reproduced over several molding cycles. The resulting pressure curve is presented in Figure 2. The maximum molding pressure was near 140 bar, which was still on the save side for the available machine, which had a pressure limit of 200 bar.

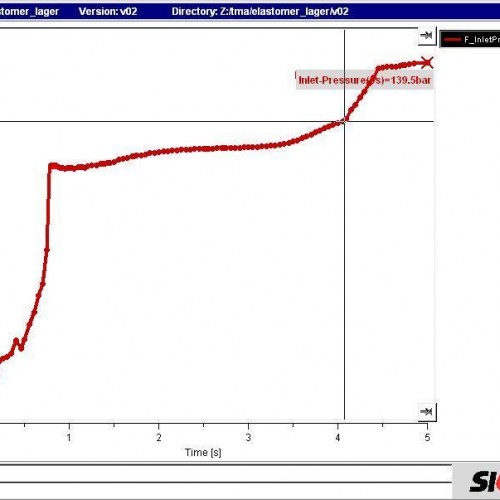

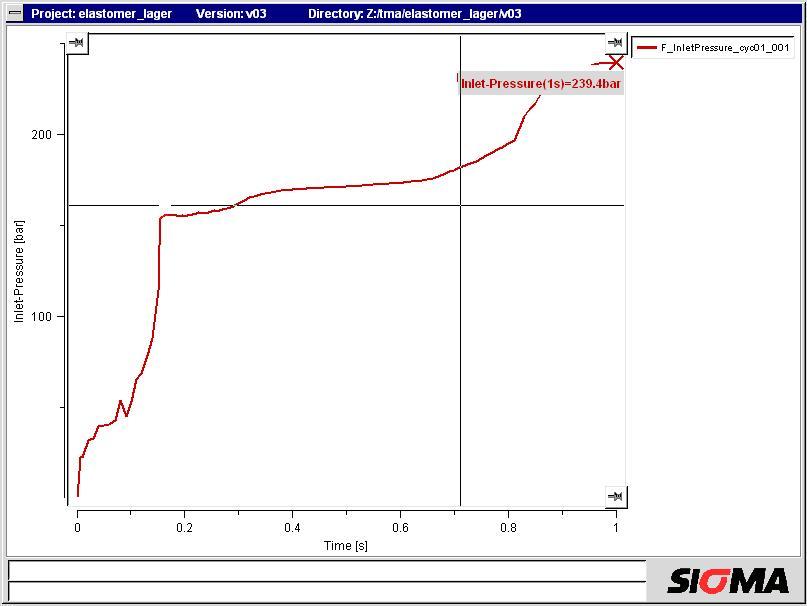

Once this research was completed, it was necessary to assess the possible pressure variations produced by deviations in the processing window. A new process set up was evaluated, which produced an overall drop in the insert temperature after several molding cycles and therefore increased the melt viscosity. The resulting inlet pressure is shown in Figure 3. In this case, though the course of the curve is similar to Figure 2, the maximum pressure was found to be 240 bar, well above the machine limit. Thus the simulation showed that the machine would only work under certain processing conditions.

Another important parameter for mold design and machine selection is the clamping force. With insufficient clamping force the mold will leak, with the formation of flashes and possibly damage of the parting plane. When molding elastomers, the opening of the mold can lead to significant loss of holding pressure and scorch, thus reducing the mechanical properties of the final part.

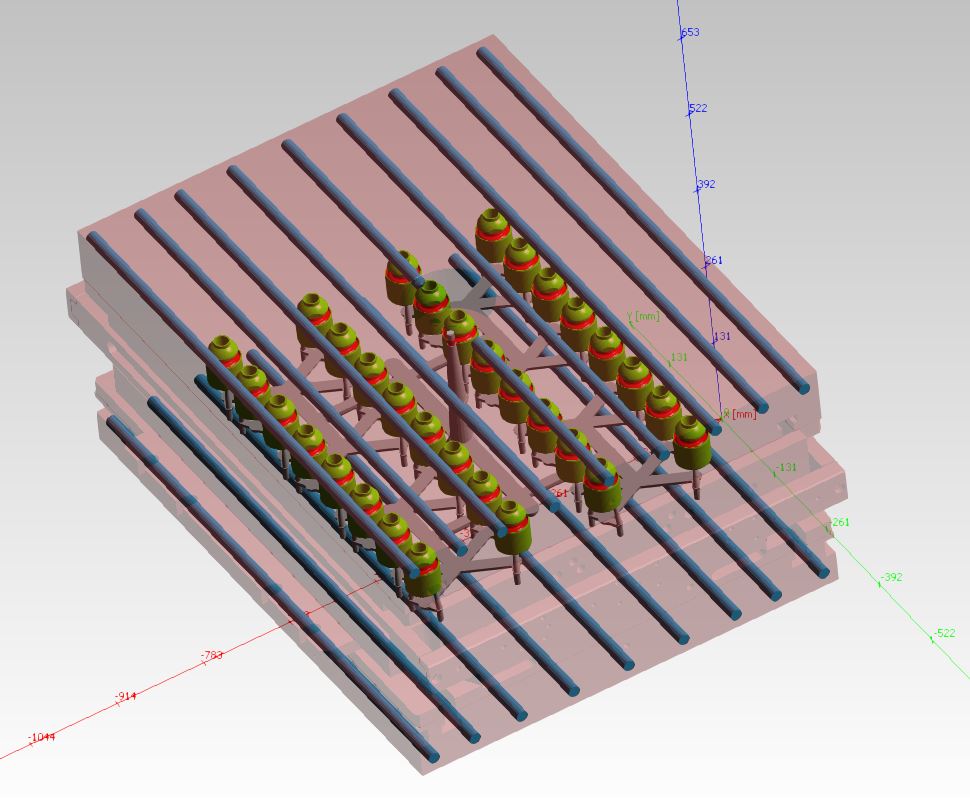

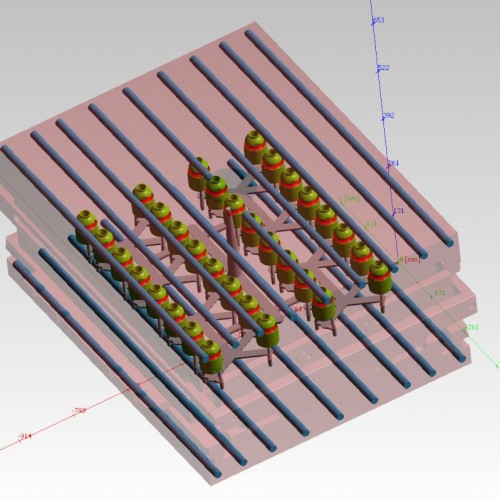

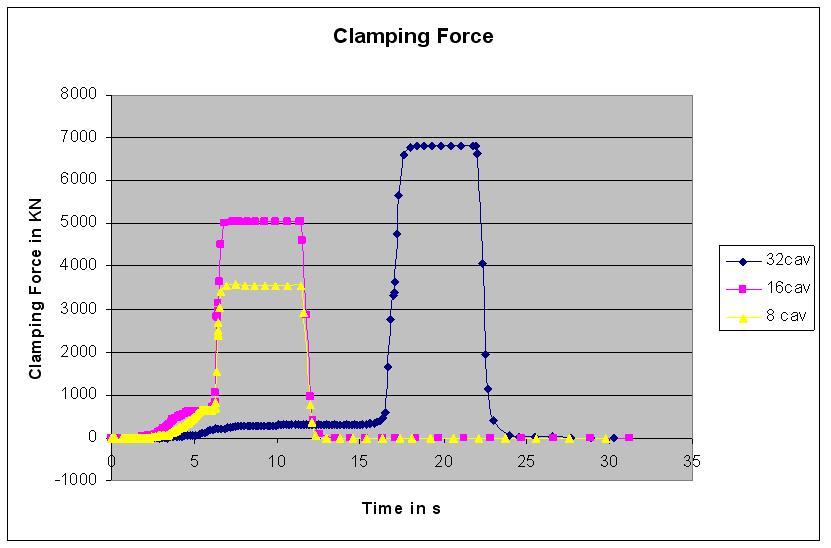

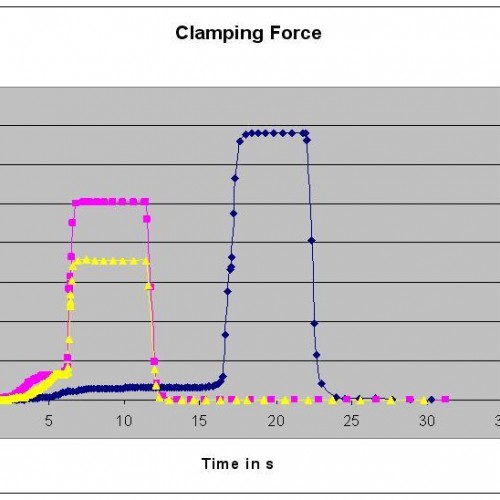

Also the calculation of clamping force is not trivial and requires attention to how several molding parameters affect each other. A mold was to be scaled from 8 to 32 cavities (Figure 4). In this case, several scenarios were considered to evaluate the resulting clamping force, as presented in Figure 5. It can be seen that though the number of cavities increased by a factor of 4, the required clamping pressure was only increased by a factor of 1.94. This means that the upscale in productivity does not imply a machine with a clamping unit four times larger, but can be achieved in a machine with only twice as much clamping force as the original configuration. This knowledge translates in important investment and energy savings.

Again, the holistic approach of SIGMASOFT® Virtual Molding and its closeness to molding reality allowed an accurate prediction and consequent energy savings.