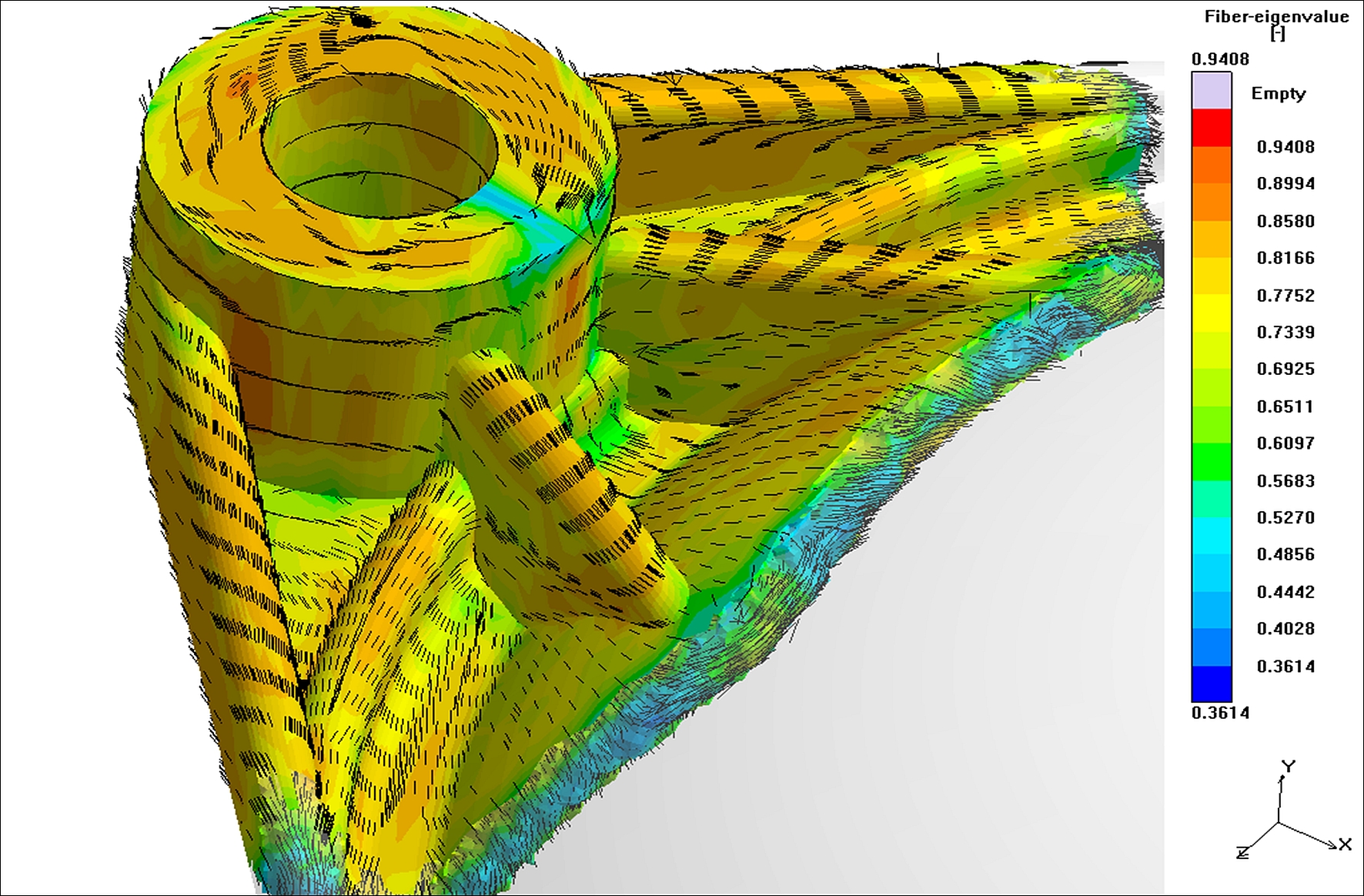

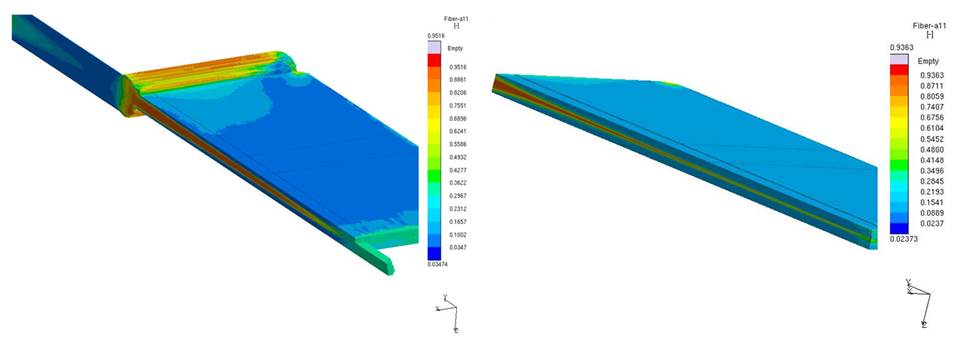

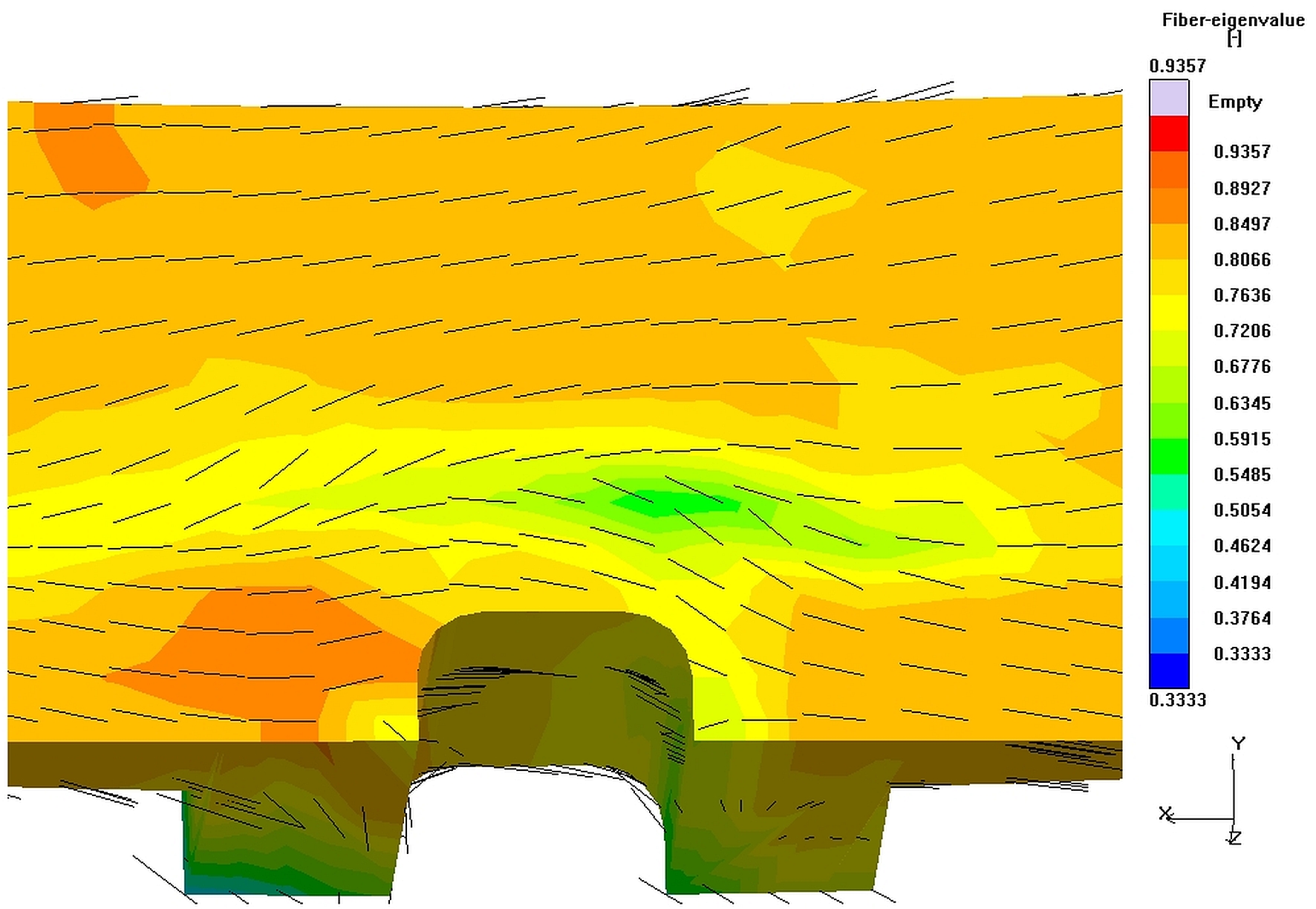

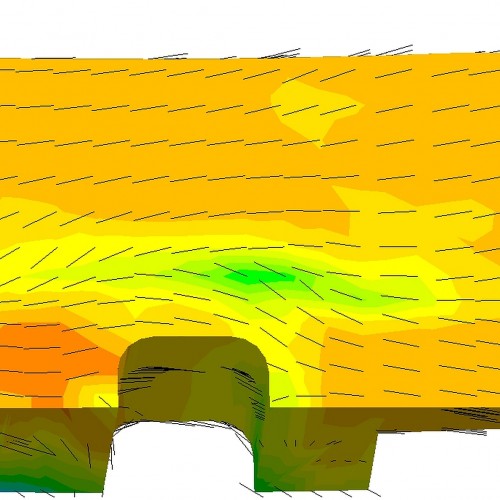

Typical failure prediction for mechanically loaded components is unable to consider fiber orientations and other anisotropies within the component. However, fiber orientations and weldlines, including the anisotropic properties incurred, do in fact play a major role in the mechanical dimensioning and local mechanical properties of components.

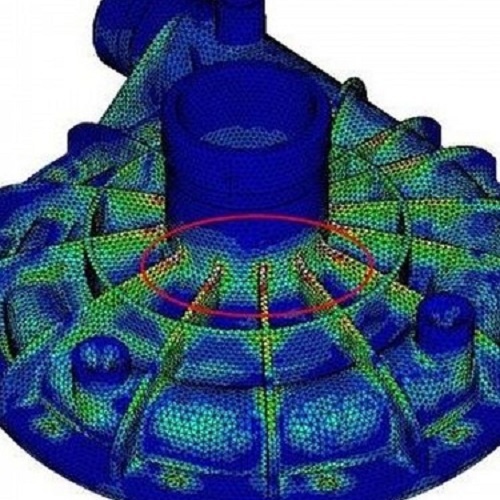

A collaborative project with Ford research center Ford Research & Advanced Engineering in Aachen and MATFEM Partnerschaft Dr. Gese & Oberhofer, was carried out to develop a new approach of integrative simulation. Based on the results obtained from injection molding simulation by SIGMASOFT®, this approach uses material properties measured in a defined direction to improve the crash simulation accuracy for highly loaded plastic parts. The MF-GenYld+CrachFEM material model developed by MATFEM utilizes the fiber orientation tensors and weld line information supplied by SIGMASOFT® and transfers them into local anisotropic part properties. Based on these local anisotropic properties, the results generated by subsequent crash simulation are therefore extraordinarily reliable in two respects, i.e. deformation behavior, as well as actual failure of the part. The integration of injection molding and crash simulation offers Ford the possibility to make development processes more efficient, significantly improve component quality and reduce over dimensioning.

The results of the process simulation are particularly suited for the realization of the integrative approach as SIGMASOFT® calculates the complete injection molding process with the entire 3D part and mold over several injection cycles. This detailed approach provides a high level of understanding about the specific reasons for failure. Virtual injection molding allows leading companies to optimize injection molds and processes before the first part is ever molded.

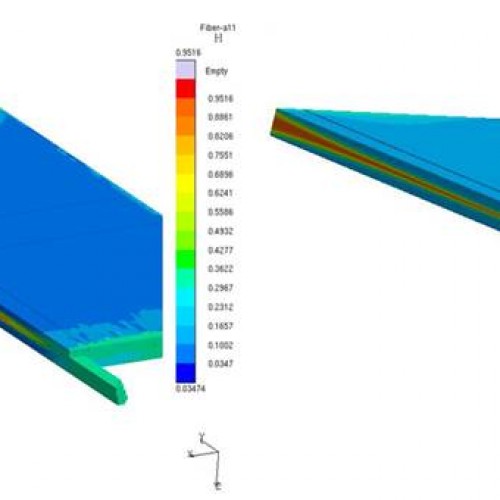

SIGMASOFT® is based on over 25 years of 3D process simulation development and is particularly suited for highly filled polymers because only a 3D simulation can capture the rheology and process effects on fiber orientation. Most importantly, as the percentage of fiber content increases, the influence of the fiber on the melt flow behavior becomes stronger. The melt flow behavior changes the filling pattern due to the higher fiber concentration and thus the fiber orientation itself is also affected, leading to changes in local material properties. Also, SIGMASOFT® has the unique ability to export the 3-dimensional weld line information of the entire part cross section.

Proprietary software, SIGMAlink, is used to map the process simulation results; weldlines, fiber orientation tensors, residual stress, etc. from SIGMASOFT® to other mechanical load analysis software and can thus be used in numerous FEM packages. The collaborative project with Ford and MATFEM employed the LS-DYNA® and RADIOSS® crash simulation packages.