Optimized for initial production

Günther Heisskanaltechnik successfully relies on Virtual Molding

Company: Günther Heisskanaltechnik GmbH

SIGMASOFT® user: since 2010

Main application: Dimensioning and optimization of hot runner systems

License: Thermoplastic (Floating)

Website: www.guenther-hotrunner.com

In 2017 the company Günther Heisskanaltechnik was even awarded the SIGMA AWARD for its success. Every three years, we present the SIGMA AWARD at the international user meeting to customers who develop innovative and successful solutions with SIGMASOFT® Virtual Molding. The Günther company received their award for successfully increasing efficiency in the injection molding process.

The use of hot runner systems is a proven means of increasing efficiency in the injection molding process. Cycle time reduction increase in quantity and reduction in rejects are just some of the goals that can be achieved by using a perfect hot runner system. Günther Heisskanaltechnik GmbH has been supporting its customers to achieve these goals since 1983. Since 2010, Günther Heisskanaltechnik has been using SIGMASOFT® Virtual Molding for the design and optimization of hot runner systems - before they are produced. A well-rehearsed team of process engineers and application technicians use a SIGMASOFT® multi-user license to detect potential problems before the production of systems and to correct them before serial production. This saves hot runner iterations and ultimately time and money for the company and the customer.

"Since the use of Virtual Molding, there are practically no more returns from hot runner manifold systems." - Mr. Dipl.-Ing. Marco Kwiatkowski, Head of Production and Thick Film Development.

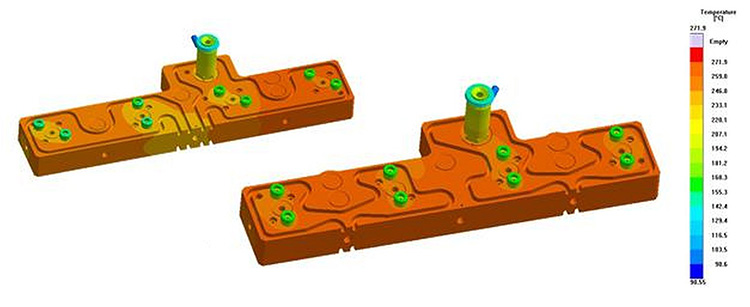

The Günther company, for example, uses heat calculation in Virtual Molding to optimally design the constructed hot runner systems regarding heat distribution. This is because Günther realizes many applications for engineering plastics, which usually have only a very narrow processing window. For special manifolds, it is therefore very important to make a calculation in advance. The present example shows a thermal calculation of a distribution system with corresponding temperature distribution after a multi-cycle analysis. The figure shows the initial state on the left and the variant improved by virtual molding on the right. The optimization achieved a much better homogeneity in the temperature distribution of the distribution system. The calculated temperatures of the optimized variant are so precise that only a small deviation of maximum 2 °C was measured. The precise design of the heat distribution made an even filling of the cavities from the first shot possible and saved the customer from speculative rework.

After the experience with more than 500 projects in 10 years of use, the typical working time at Günther Heisskanaltechnik, for a simulation, is about 2.5 hours. Before the use of simulations, reclamations occurred, which led to increased expenditure, e.g. by using service specialists and returning the system, which usually involved additional conversion costs. Problems or causes often could not be clearly identified and led to several change loops. The costs often added up to a five-digit amount.

Added to this are indirect costs for the customer and, above all, his dissatisfaction. Careful design of hot runner systems is therefore essential to minimize costs and increase customer satisfaction.

Current precision systems require not only an exact and reliable prediction of heat distribution, but also of pressure loss - especially with demanding materials. Günther Heisskanaltechnik invests this care both in the pressure loss calculation and in the thermal design and thus significantly reduces change loops while at the same time increasing customer satisfaction. Thus, there is no need for subsequent optimization and revision of the systems delivered. The saving of optimization loops and reworking creates additional capacities in product development and increases effectively and noticeably the economic efficiency.

In addition to the software, Günther also relies on the know-how of the SIGMASOFT® team consisting of engineers specialized in the field of plastics technology.

"The SIGMASOFT® support is exemplary, and someone is always available to help you – whether you have questions regarding the process or the software", says Dipl.-Ing. Marco Kwiatkowski when asked about customer support.