A part made out of polycarbonate with 10% glass fiber (Figure 1) was to be produced by injection molding. As the part had to be assembled, it was paramount to obtain a reliable warpage prediction.

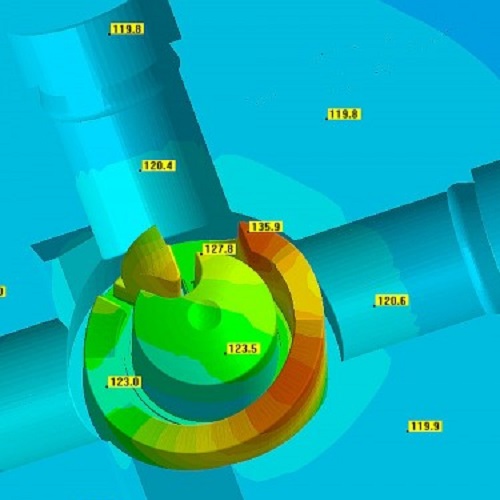

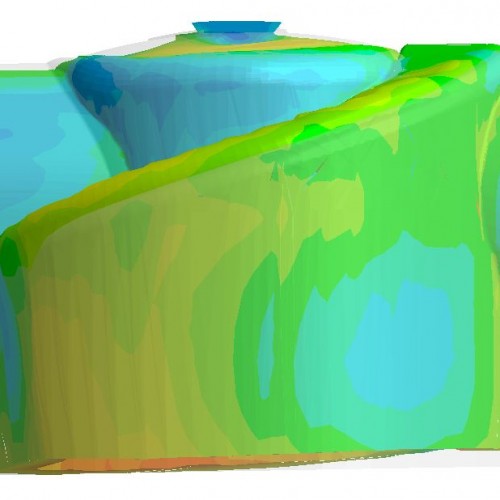

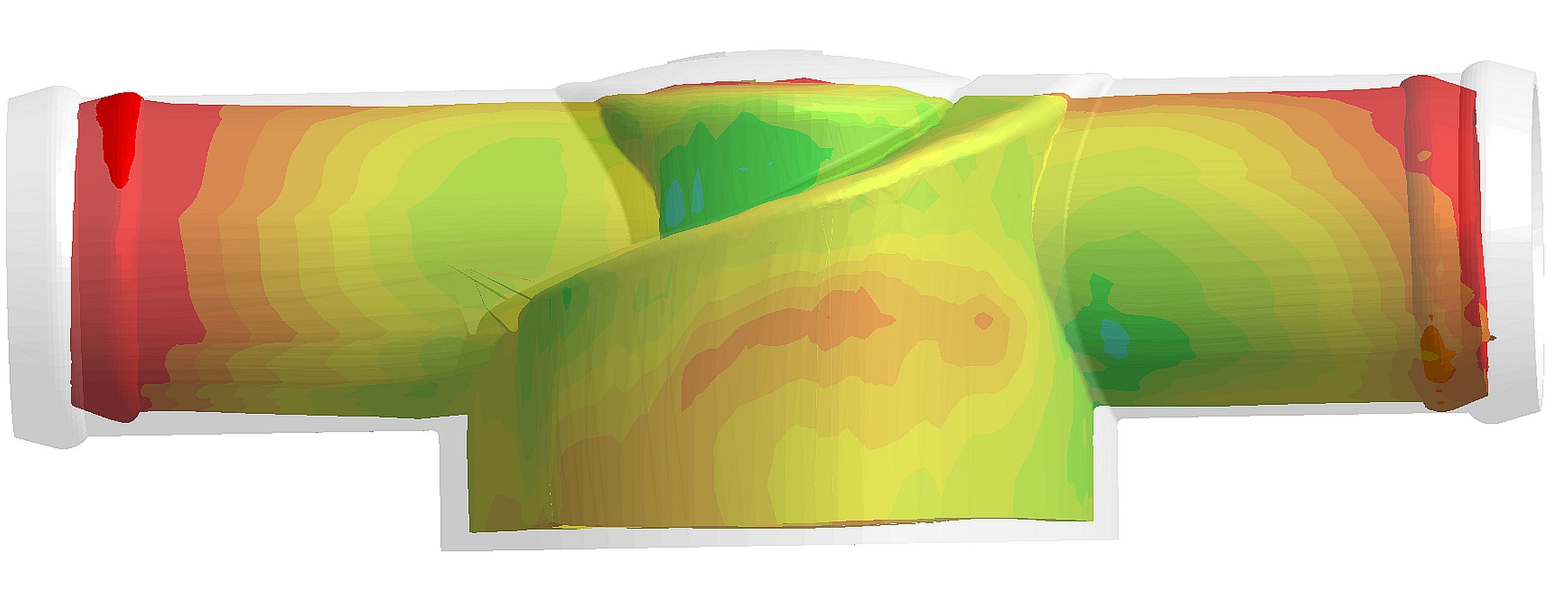

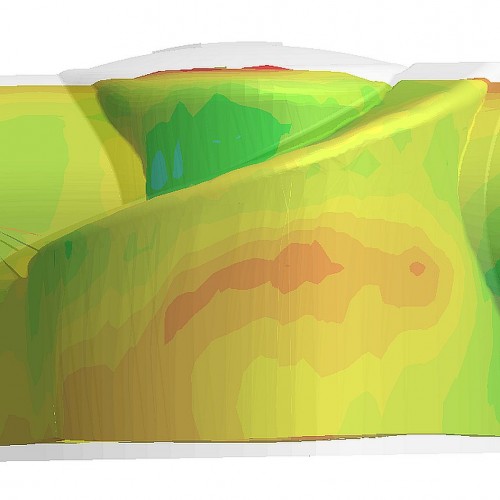

At first, a conventional simulation approach was used to predict the deformation. Under this approach, the mold was assumed to have a uniform temperature. Only one molding cycle was simulated comprising the stages of filling, packing and solidification. The warpage predicted under the assumption of a uniform mold temperature is presented in Figure 2. The ends of the part show a downward distortion.

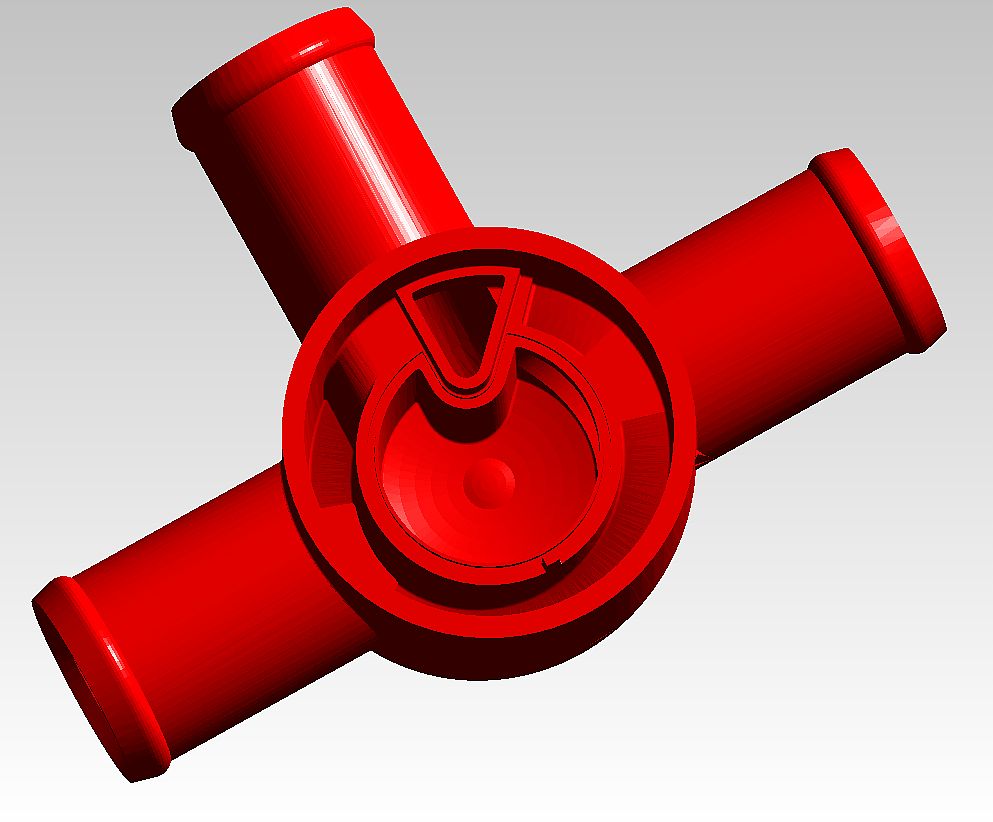

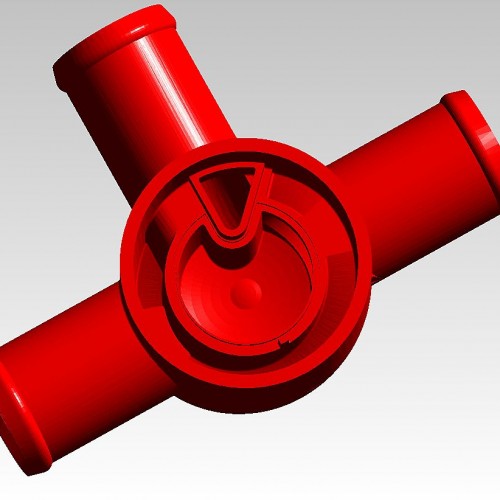

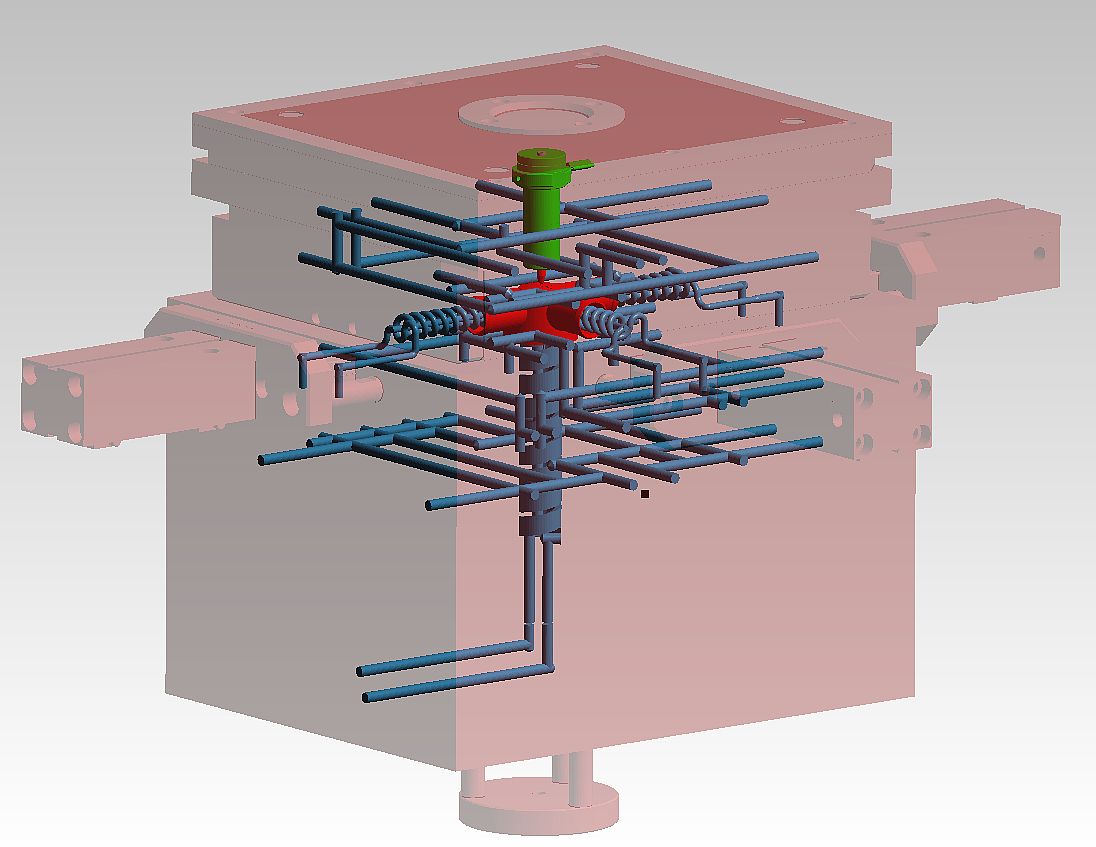

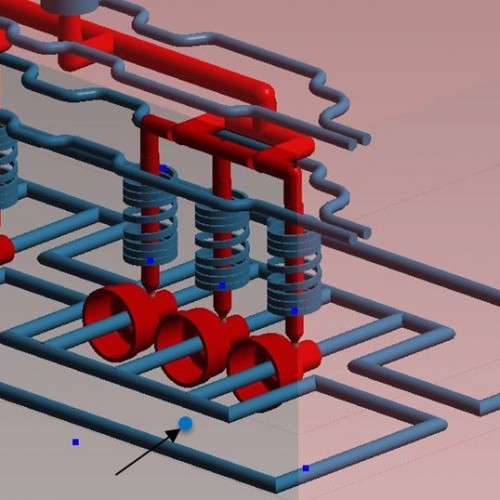

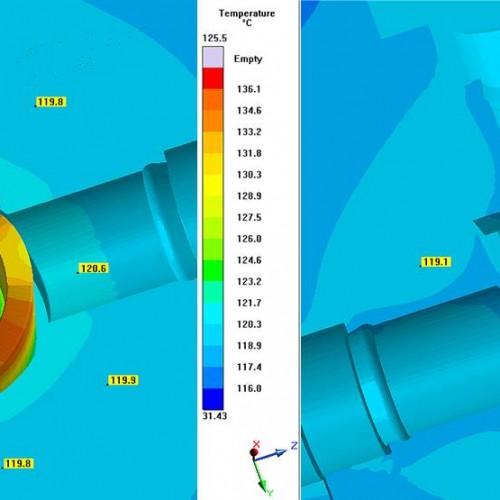

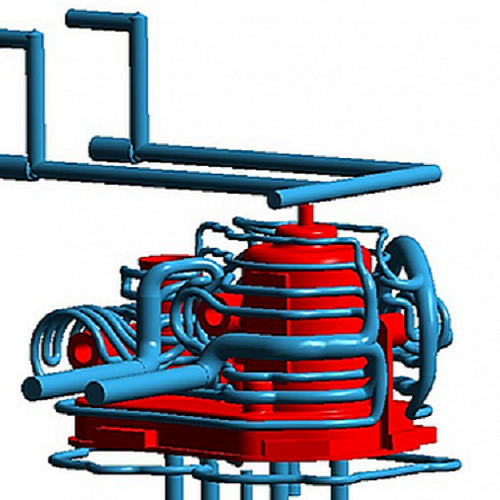

For a second simulation SIGMASOFT® Virtual Molding was used. Instead of assuming a uniform mold temperature value, the temperature distribution in the mold was calculated. To do this, SIGMASOFT® calculates the total heat transfer between all mold components and plastic parts: the heat transfer between tempering circuits and mold plates, the influence of high-conductivity inserts, the effect of hot runner manifolds and even the heat transfer with the environment is considered in the calculation. Then, instead of just the cavity, the mold configuration seen in Figure 3 is introduced in the simulation.

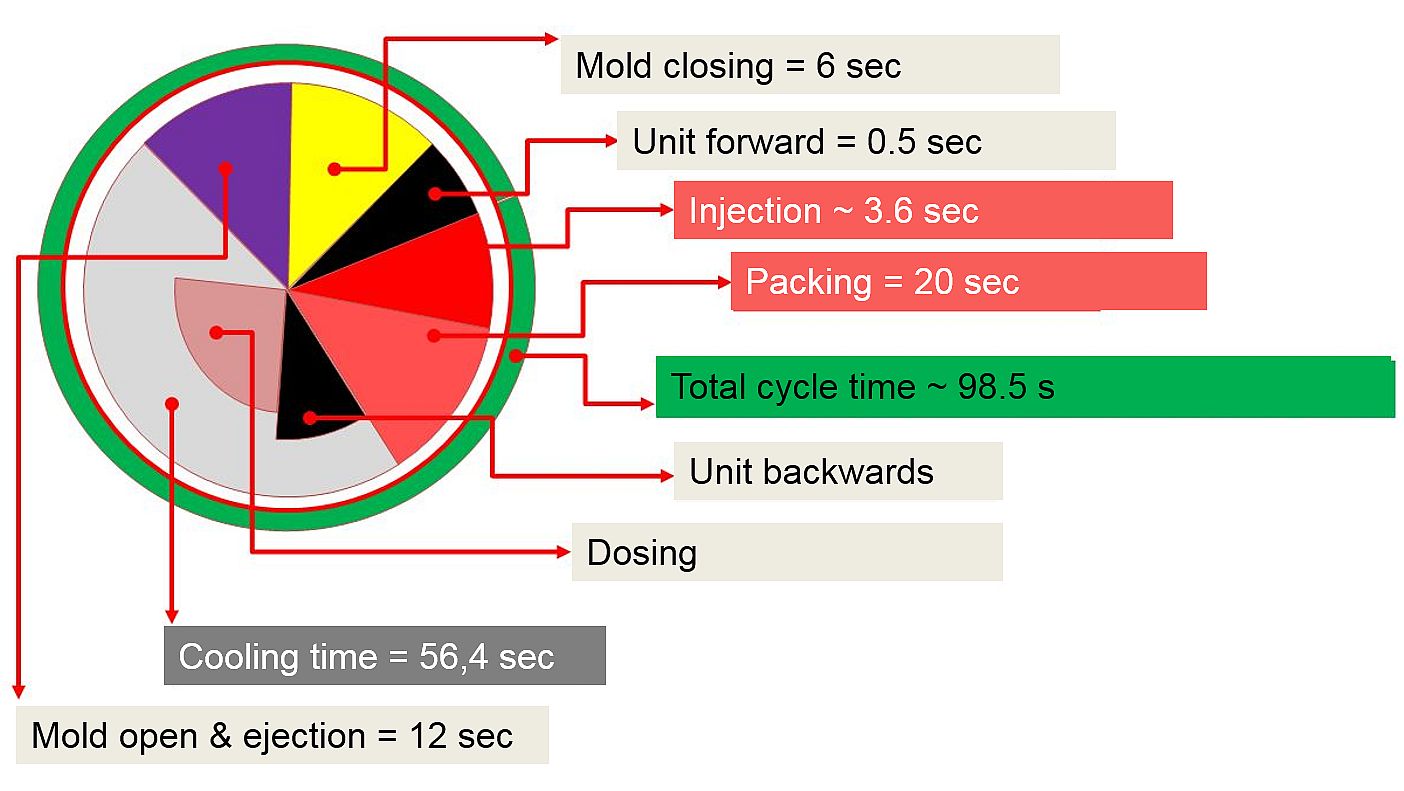

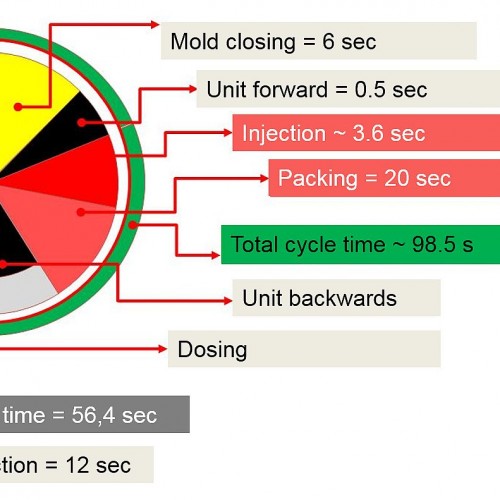

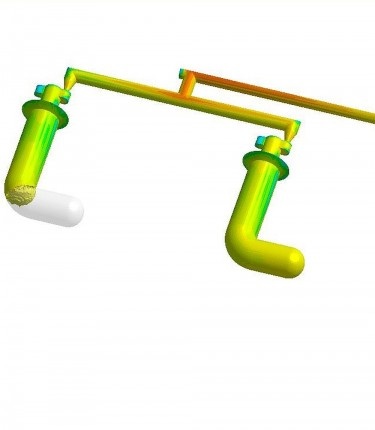

The molding process presented in Figure 4 is reproduced completely. Not only the stages of filling, packing and solidification are simulated, but also the handling times between cycles (the time required to open the mold and to eject the part plus the mold closing time). In this particular case, mold handling time is about 10% of the total cycle time. Instead of one, several molding cycles are calculated consecutively, until the mold-part system reaches a steady thermal state. Just as in reality, where several molding cycles are run prior to production start, under the SIGMASOFT® Virtual Molding approach the mold is left to stabilize until the thermal conditions between cycles are reproducible. This is the stage where quality consistency is achieved in the molded parts.

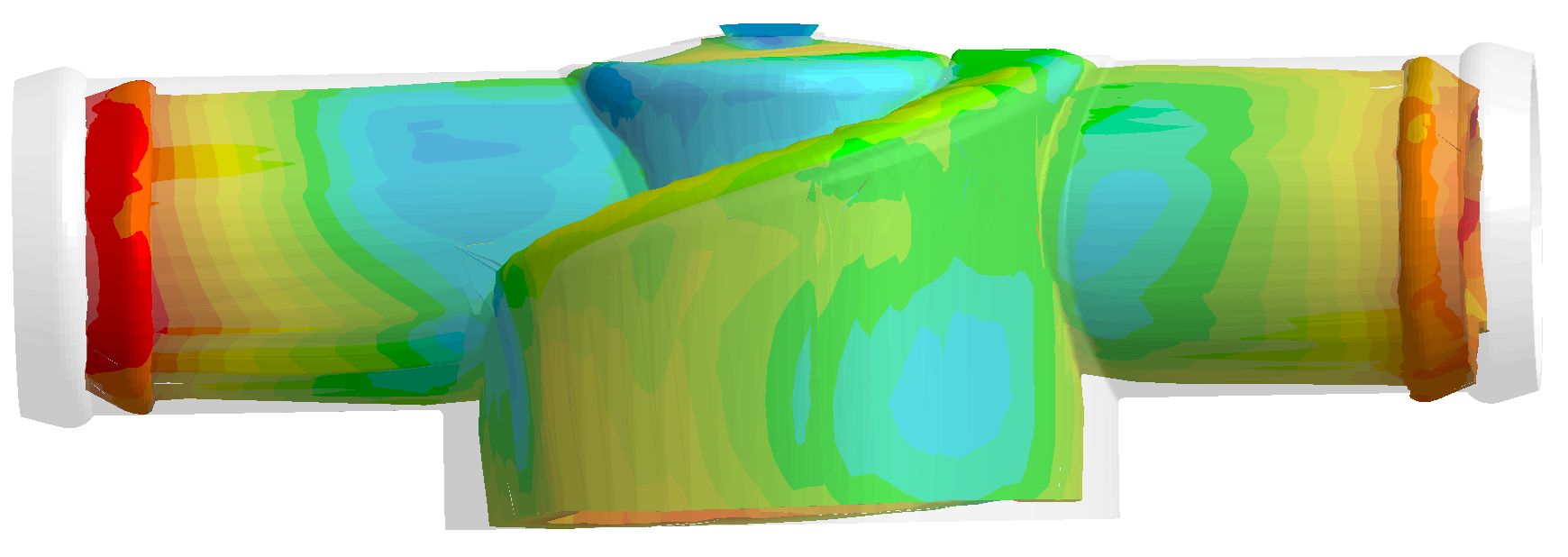

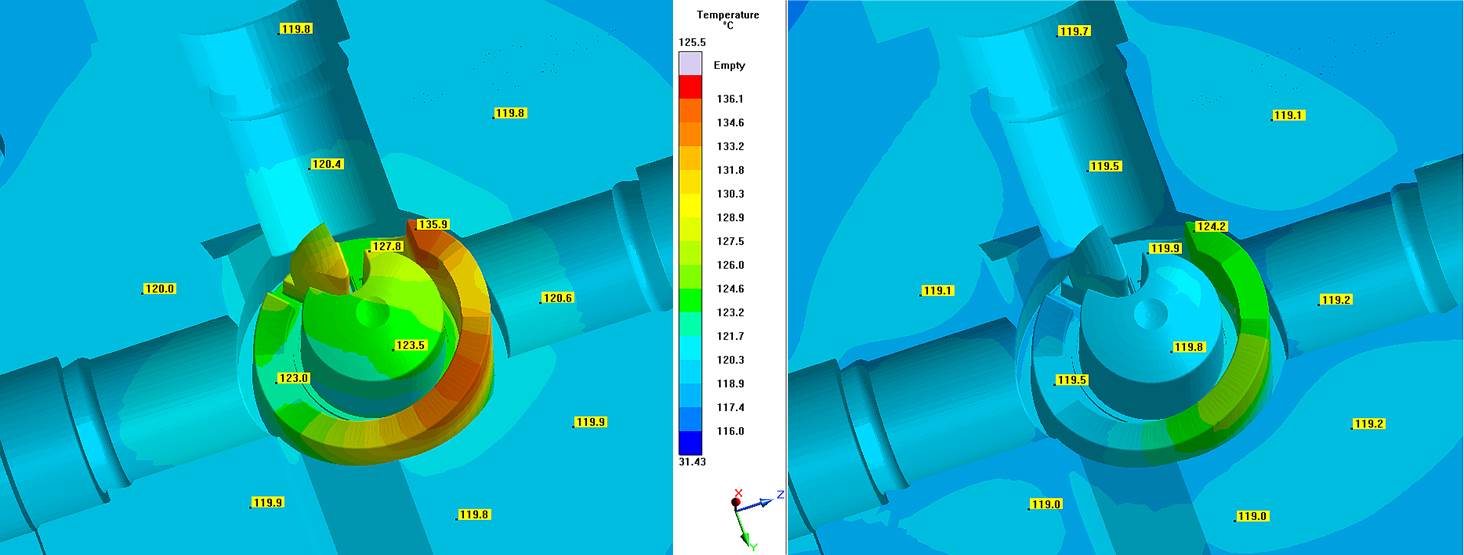

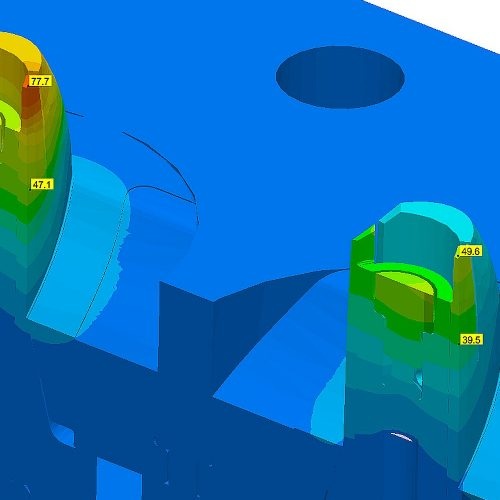

In Figure 5, the temperature of the movable mold half is presented after 10 molding cycles. The left side shows the temperature distribution right before ejection, and the right side the temperature just before closing the mold again – after 18 seconds have elapsed. In this period of time, the mold remains open, transferring heat towards the environment.

Two things are evident from Figure 5. First, assuming a constant mold temperature as a boundary condition for this part would seem to be a risky assumption. Not only is the mold temperature not constant over time, but it also shows a variance of 15°C within the cavity. Second, in the 18 seconds where the mold remains open the temperature can change locally up to 11°C, so in order to get the right picture regarding mold temperature – and consequently energy available for molecular rearrangement – it is imperative to include the real process –including handling times- within the calculation.

The warpage predicted with the SIGMASOFT® Virtual Molding approach is presented in Figure 6. The part now warps to the opposite direction compared to the conventional approach. The conditions to which the molded product is exposed in both cases are very different. The biggest difference is the ratio of polymer that solidified with packing pressure to that which solidified without packing pressure, which is a direct result of the difference in thermal energy available to produce local differences in molecular rearrangement. The assumption to use the single-cycle simulation approach, in this case, led to incorrect prediction of directional distortion.