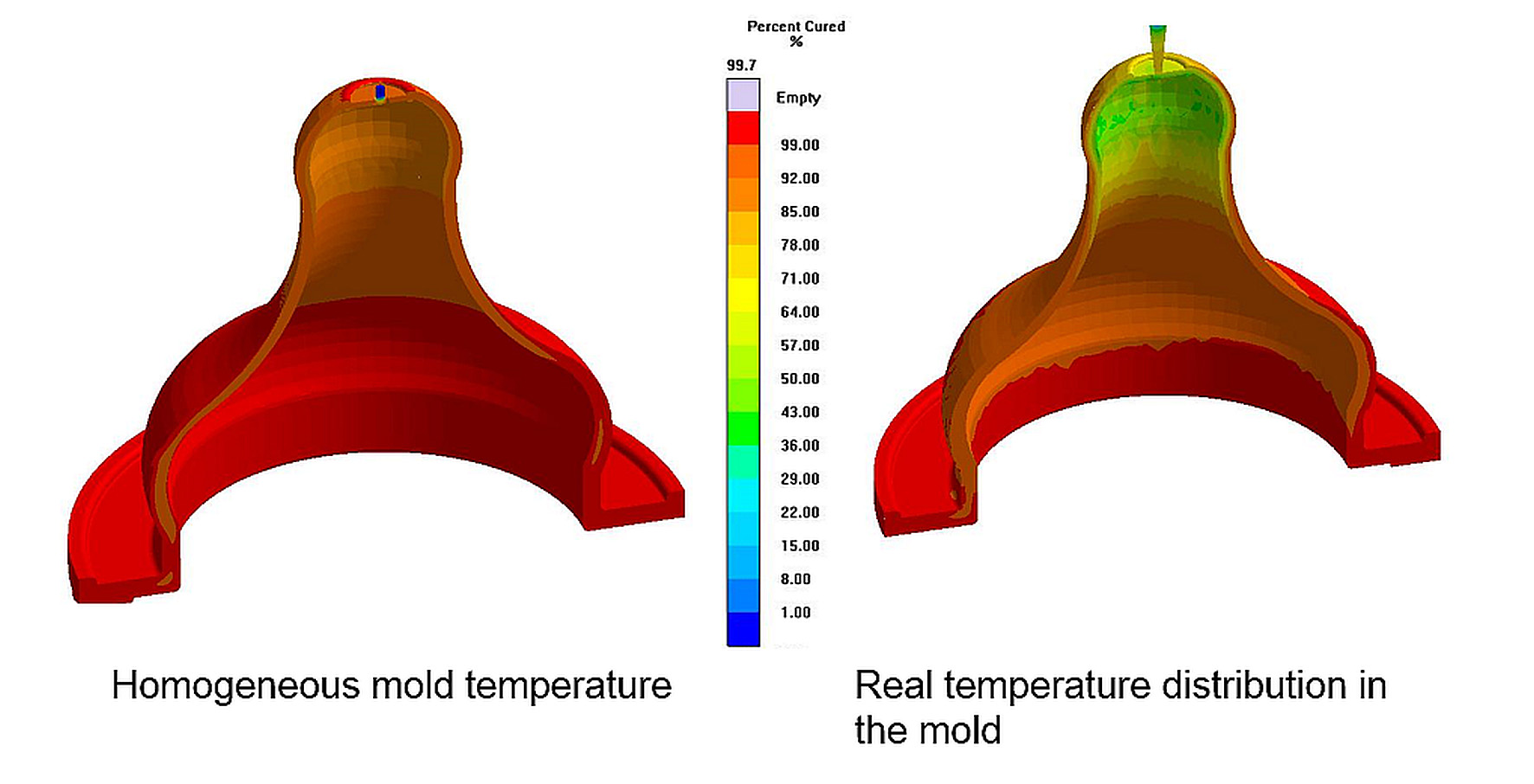

The demand for liquid silicon rubber (LSR) products is growing. Particularly in the medical and baby care markets, its high thermal stability and very good physiological properties make LSR the material of choice for an ever increasing number of applications. However, molding LSR can be challenging: because it is a reactive material, the processing window is narrow and the scrap produced cannot be re-processed. Also a proper mold venting is paramount to avoid air traps. The position of welding lines and filling patterns, such as jetting, can affect the final product quality. Additionally, a proper mold tempering must be guaranteed during the whole molding cycle, in order to ensure a cost-efficient cycle time and a good product quality.

In order to maximize profit and reduce scrap, it is important to get a deep understanding of the complete process and to anticipate possible problems, including the flow and curing behavior, as well as the tempering conditions through the complete molding process.

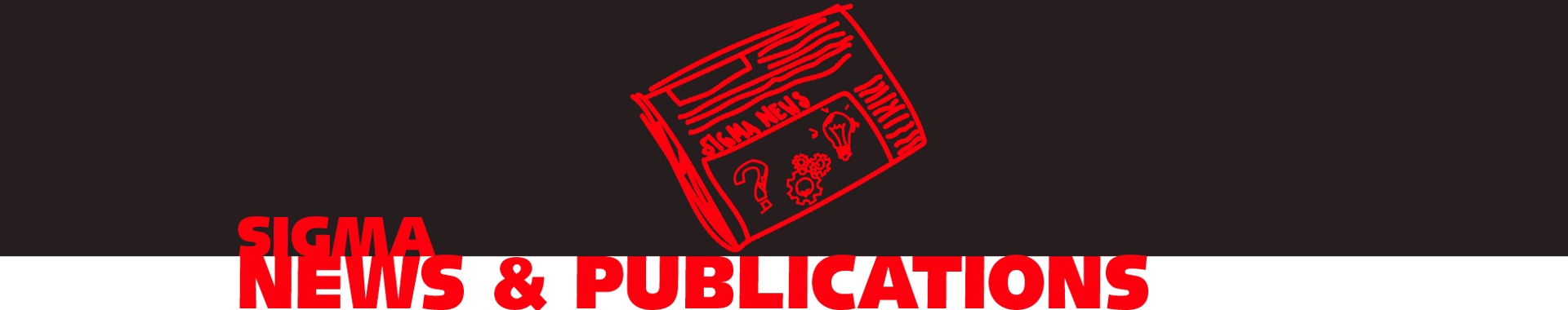

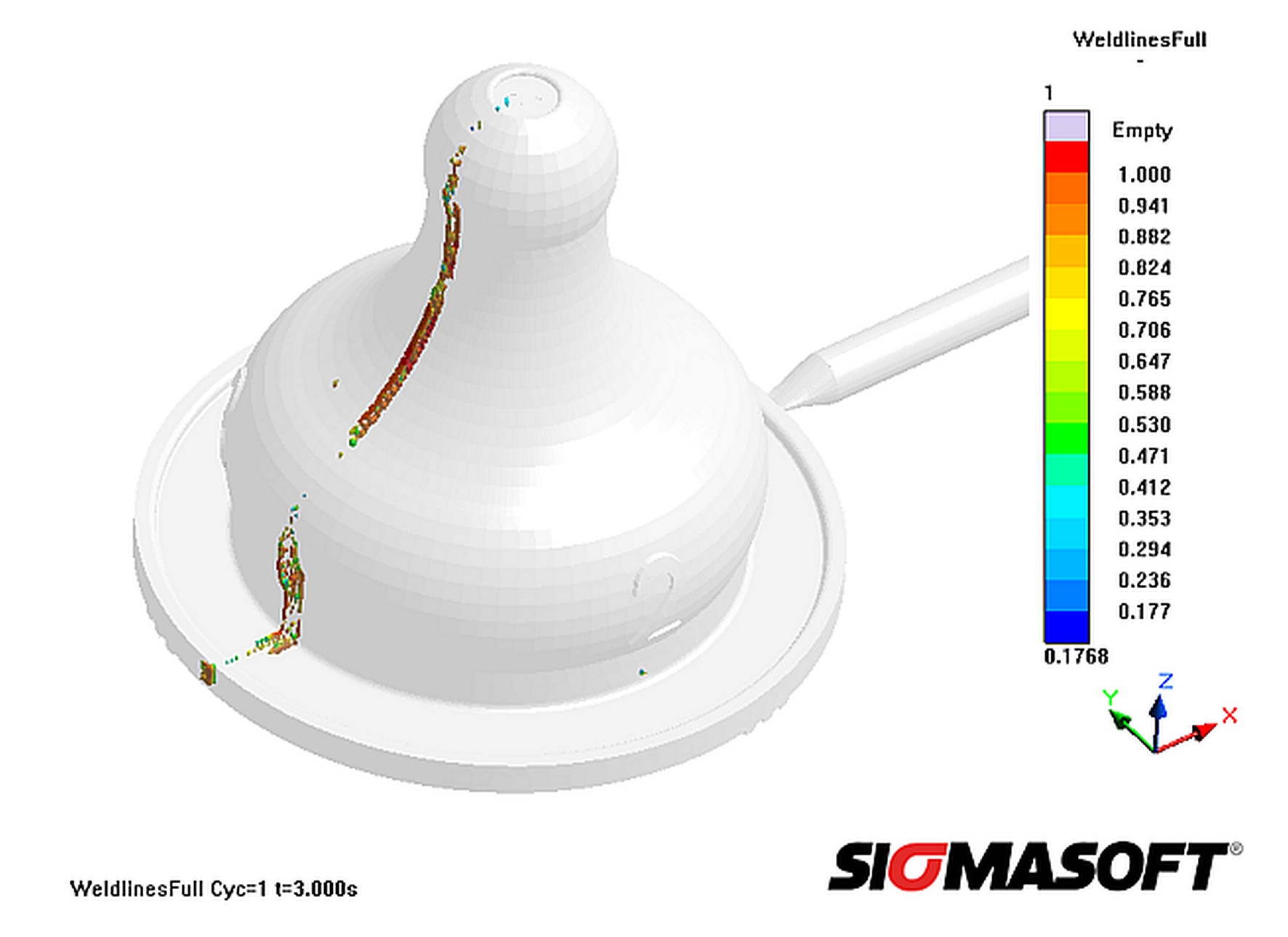

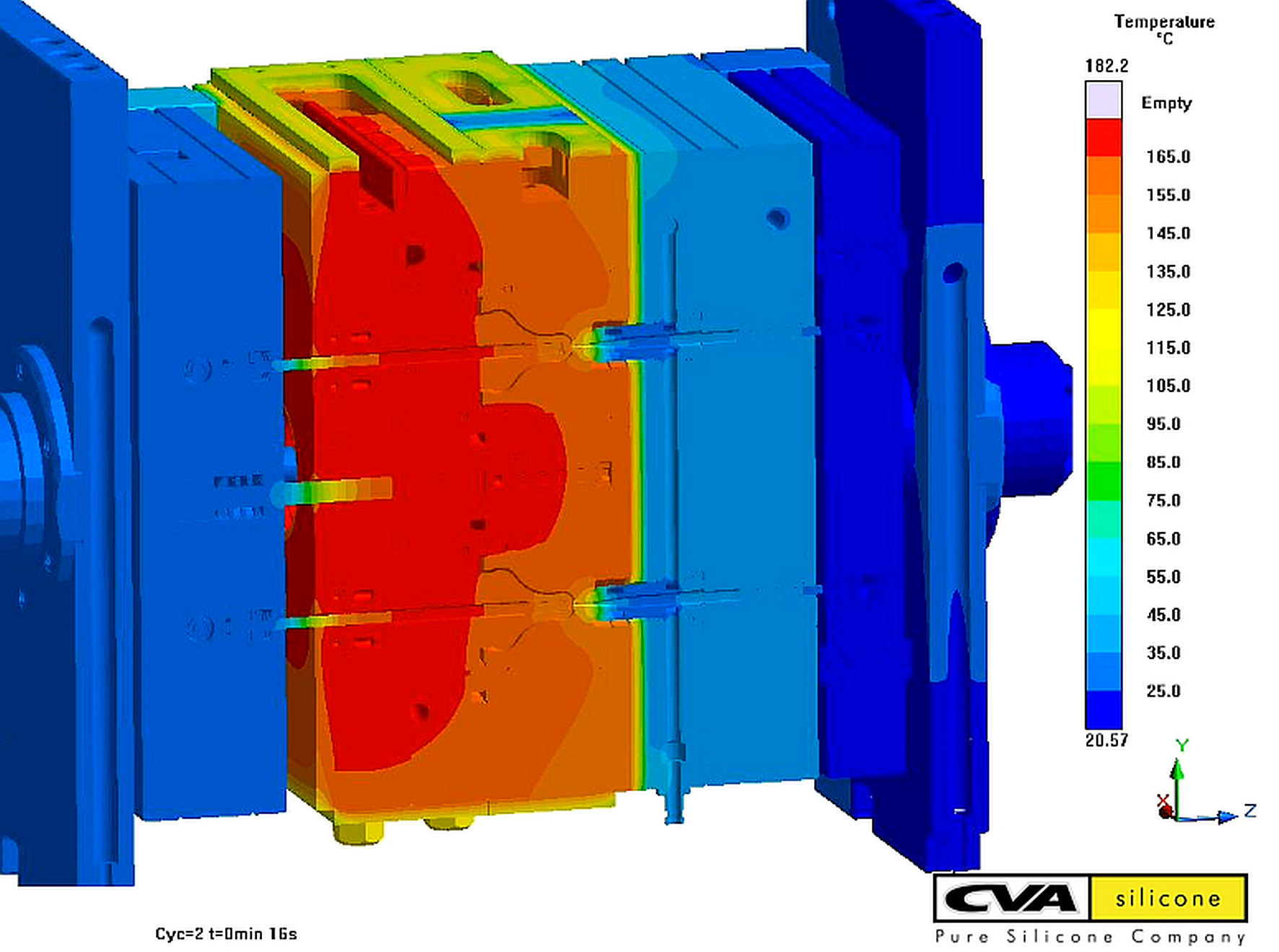

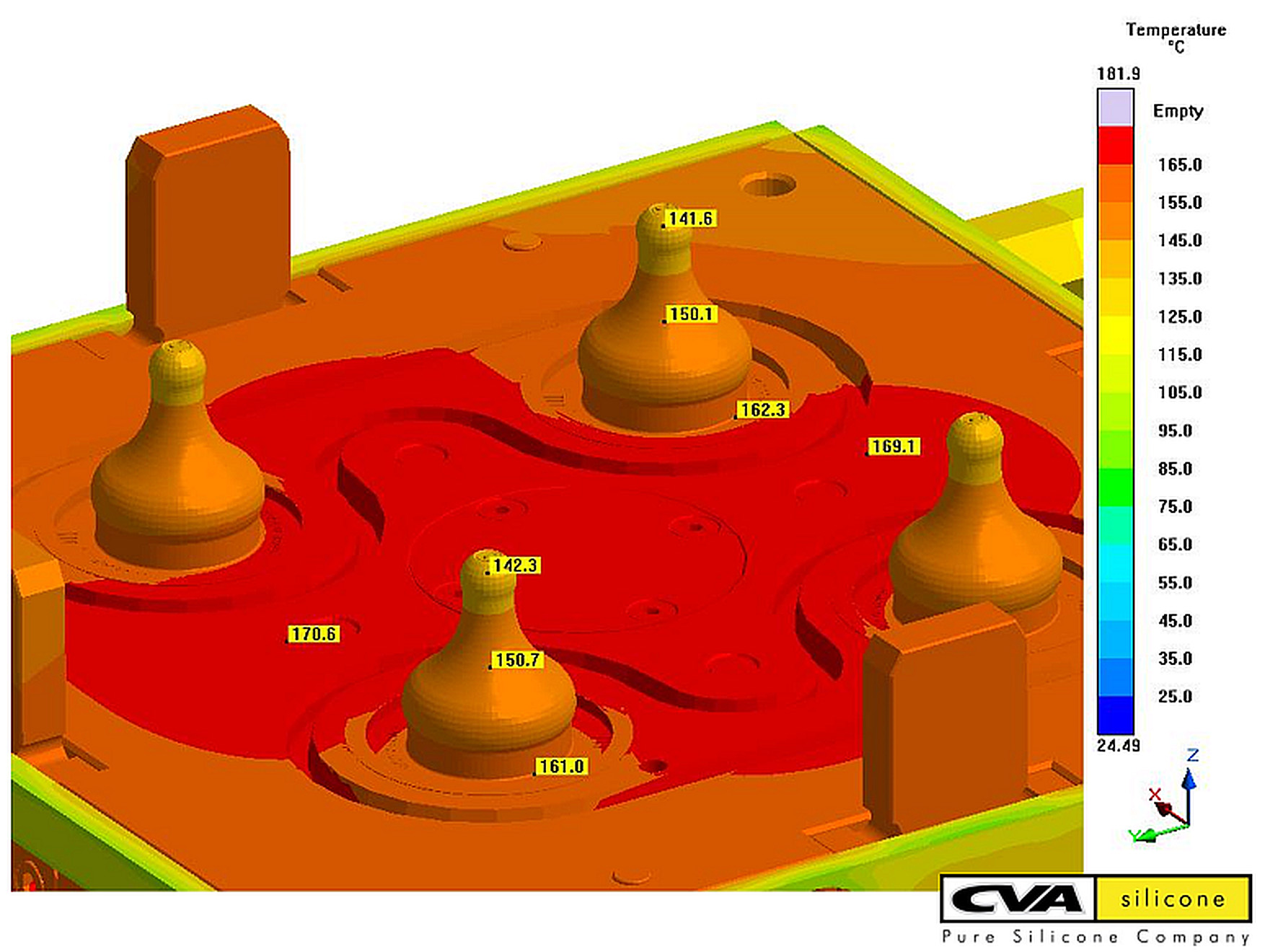

CVA Silicone, based in Saint Vidal, France, reached out to SIGMA to support the decision making process in a new four-cavity mold to produce silicon nipples. SIGMASOFT® Virtual Molding was used through each stage during mold development, to evaluate the runner design, the mold tempering and the overall efficiency of the molding system.

Finding the best runner

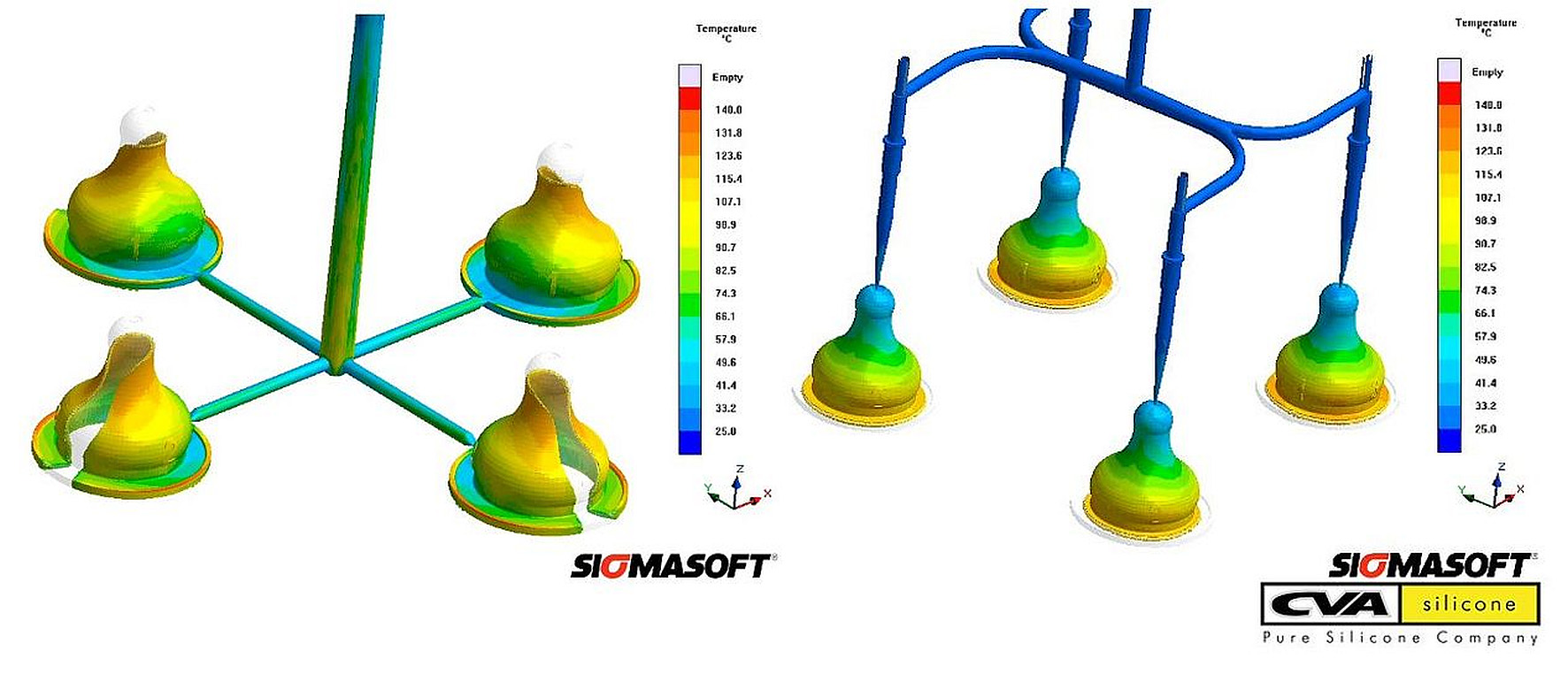

In a first approach, an X-shaped runner configuration, as seen in Figure 1a, was foreseen. As a traditional runner was to be used, the X-shaped minimized the scrap produced. The channels were cylindrical with a minimum diameter of 4 mm. Still, the runner volume represented 52% of the total shot volume. A first filling analysis with this configuration showed furthermore that weld lines would appear along the part, as seen in Figure 2, an undesirable outcome both for mechanical integrity and part aesthetics.

The alternative of using a cold runner was considered. In a cold runner, no material reticulation takes place, and therefore no scrap is produced. However, due to the additional investment required, the feasibility of this approach had to be carefully evaluated.