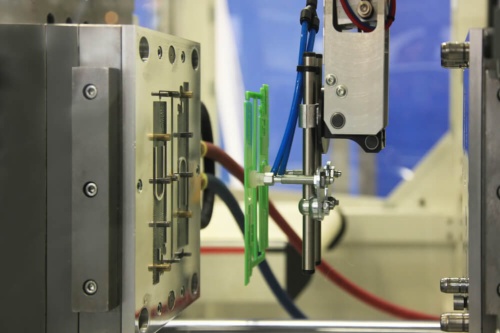

A Virtual Injection Molding Machine

A new project was just received. As usually requested, this new part has to be better than the previous one. This new part has more expected of it performance wise and, of course, it has to be cheaper. Oh – plus, in the coming years the price is expected to decrease further (we are part of the automotive industry). Because of this, a dependable strategy for optimization is required. Especially since costs for workers, raw materials and machines tend to increase over time.

Available approaches

What makes this tricky is manufacturing location, machine, mold and material are virtually fixed with approval of the PPAP (Production Part Approval Process). The question now is, where is it possible to detect saving potential in process design, material consumption, rework, scrap reduction and shorter cycle times? Scouting for the cost-drivers, using a virtual injection molding machine like SIGMASOFT Virtual Molding can be eye opening. This simulation software allows process engineers to try out a variety of ideas in detail (or have them automatically calculated as DoE / design of experiment).

Typical questions to improve the running process can be:

- How can making changes to gating improve the end result (thermal balance, material savings)?

- What contribution does thermal insulation bring to the process?

- What is the effect of changes to various process parameters (heating-/cooling times, injection speed, holding pressure)?

- How are the defects in some parts related to high scrap rates and rework?

During process optimization all, or a combination of these points have to be considered and worked through. Even a small decrease in cycle time can result in improvements of machine costs per part. Looking for ways to reduce cycle time should always be considered. Another example to evaluate is the use of hot runners (or cold runners in elastomer applications). The save material waste of lost runner systems and allow different processing windows but does the investment pay off?

Advantages of simulation

In the prototyping center due to the limited capabilities of smaller and less complex molds, not all aspects of production can be accurately considered. This is important to mention because it’s impossible to consider all of the factors that will come into play in the full production environment. Once a part is in production, trial and error experiments on the shop floor are unrealistic. However, through simulation software any design, process or material change can be evaluated. The entire process window can be evaluated at once in a single simulation. Knowing the end-result before any update is of great help to making decisions efficiently for a robust process and optimization of running parts.