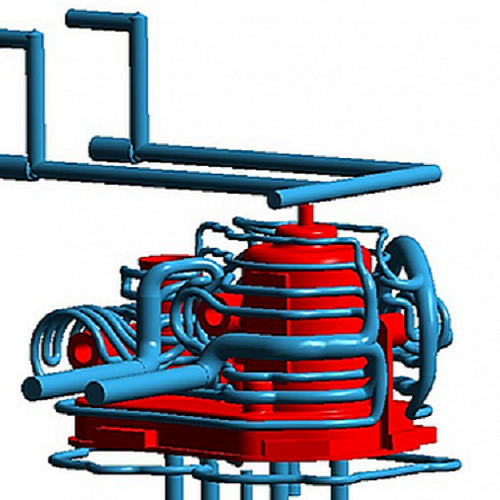

In the very early stage of part development, when not much more than the part properties is known, SIGMASOFT® Virtual Molding can help optimizing the gating systems and the runner balancing. Where gates should be placed? How many cavities is the optimum for a mold? What about the runner balancing? How robust is the runner balancing against small changes in viscosity or temperature?

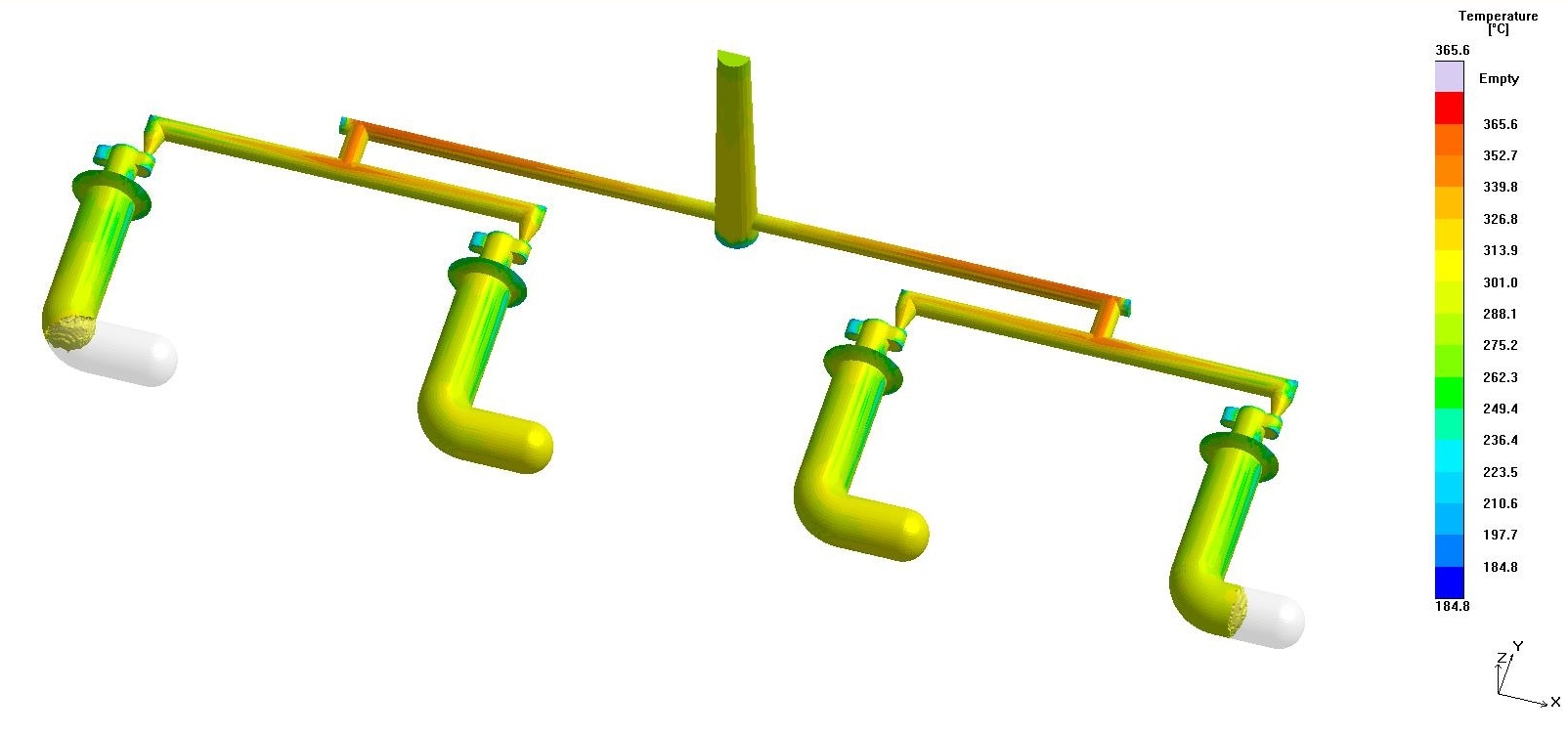

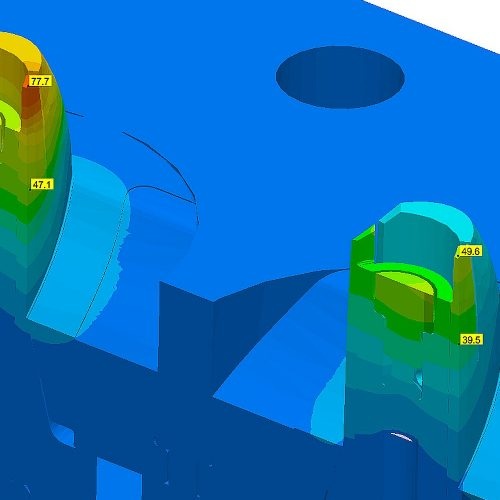

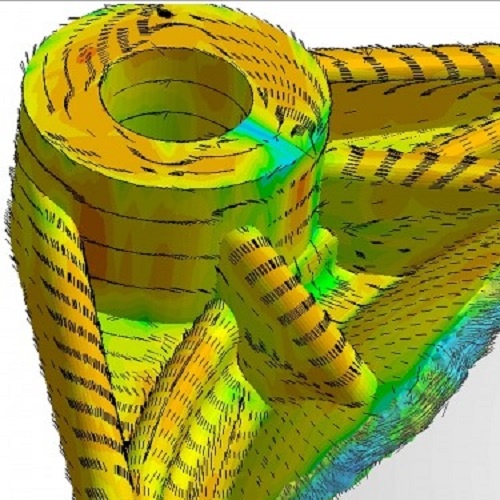

A simple simulation, set up in five minutes, delivers a first impression about how good the part and runner system are behaving. The figure shows unbalanced filling of four cavities. The temperature is shown in the colored scale. Due to differences in shear heating, the inner cavities fill faster than the outer cavities: because the polymer melt “bends” repeatedly in the inner cavities, it suffers more shearing and therefore more shear-thinning (its viscosity is reduced).

This effect is magnified over several cycles: because the shear effect also produces heat dissipation from the melt, the mold increases its temperature locally, further decreasing viscosity. A real cavity balance analysis calls for the consideration of these combined effects: shear-dependent viscosity and thermal-dependent viscosity. Only if the time-changing thermal boundaries surrounding the melt are properly considered will the unbalanced filling be accurately predicted.